My expertise when it comes to construction projects is limited to knowing (or at least having a strong suspicion) which end of the hammer to hold onto. I have access to skilled workers, so my question is more about concept and design than actual assembly.

The local kayak club has racks to store the kayaks at lakeside. I am not enamored with the design, efficiency, or space utilization of these racks, so...

Utilizing invincible ignorance, I have thought up what I feel is a better system.

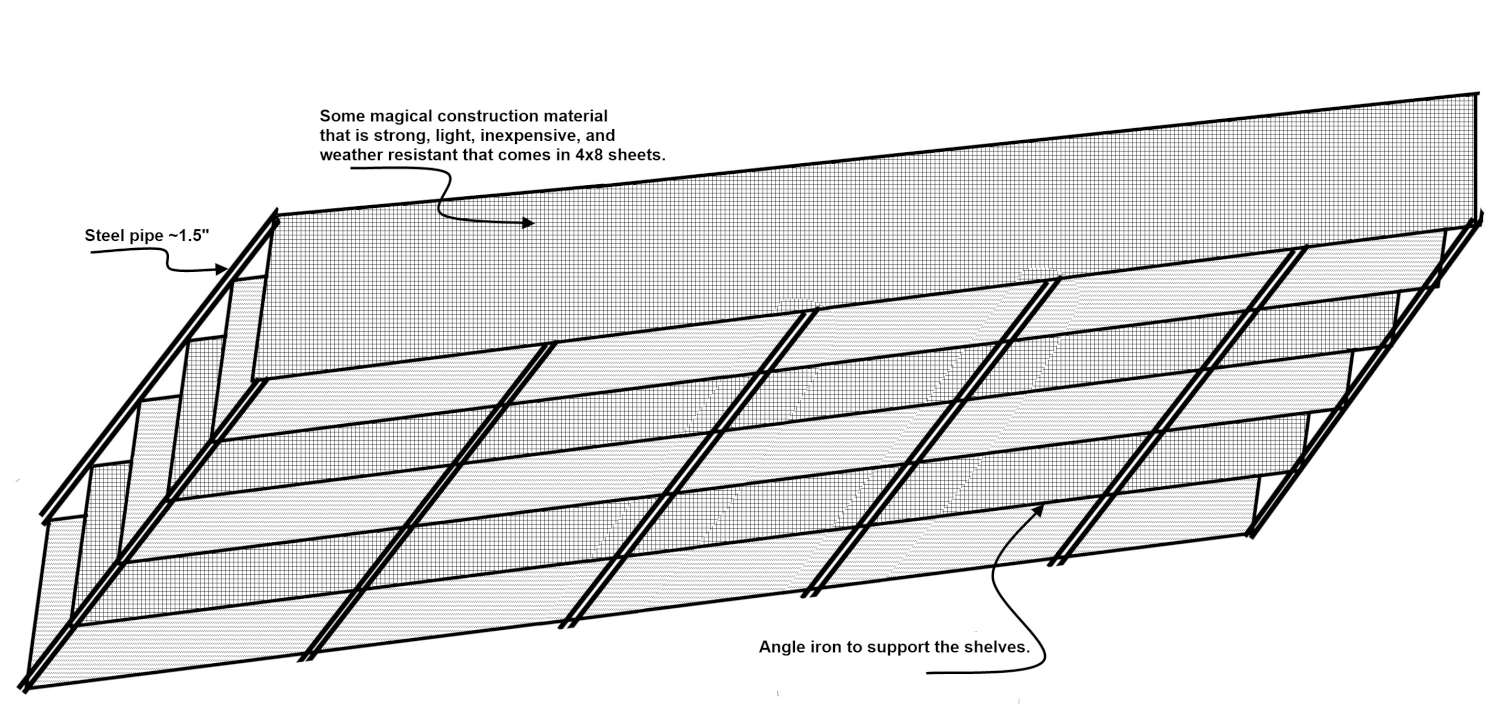

Attached is an amateurish computer sketch of what I have in mind, 7 feet tall, 20 feet in length, a bit more than two and a half feet deep. The cross hatched shelves are what the boats will rest upon and are nominally plywood, supported along their edges by angle iron welded to the supporting legs which are made of pipe. There are five shelves at 16 inches separation plus the roof.

I say nominally plywood, because that was what I could think of, but plywood is not suitable because of cost and weather exposure.

So, the question: What is the least expensive, weather resistant material I can use, both for the shelves, and for the outer skin of the rack? Each shelf of the rack will support a maximum of 65 pounds. One end of the rack will be closed like the sides, the other end will be a hinged door with deadbolt lock for access to the kayaks.

My system, in the unlikely chance that the club can afford to do it, would store 60% more kayaks in less than half the space of the existing racks, offering better weather protection, better security, far less maintenance, and vastly improved ease of access. FWIW, the ultimate plan would be to have nine of these racks in three groups so only two side skins would be required for each set of three racks, one set at 20 feet, the second at 18 feet, the third at 16 feet length.

Suggestions?

tanstaafl.

Attachments

_________________________

"There Ain't No Such Thing As A Free Lunch"